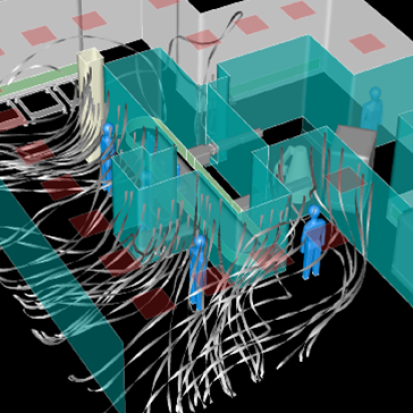

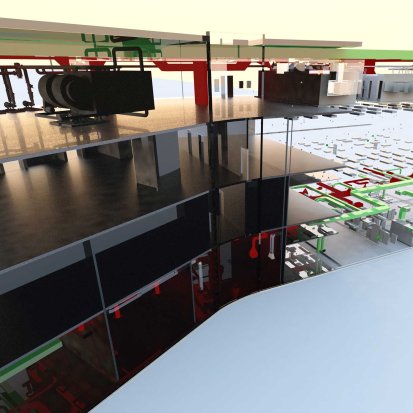

We provide electrical and mechanical engineering services that support the design of any building. Our professional engineers act as the interface between buildings and people to provide a comfortable, functional, sustainable environment. Our expertise encompasses MEP engineering and fire protection engineering services as well as CFD Modeling, BIM modeling services (utilizing Revit 3D modeling), specialty lighting design, building commissioning services, and plant engineering services.

Have a question or want to discuss a project?

contact us